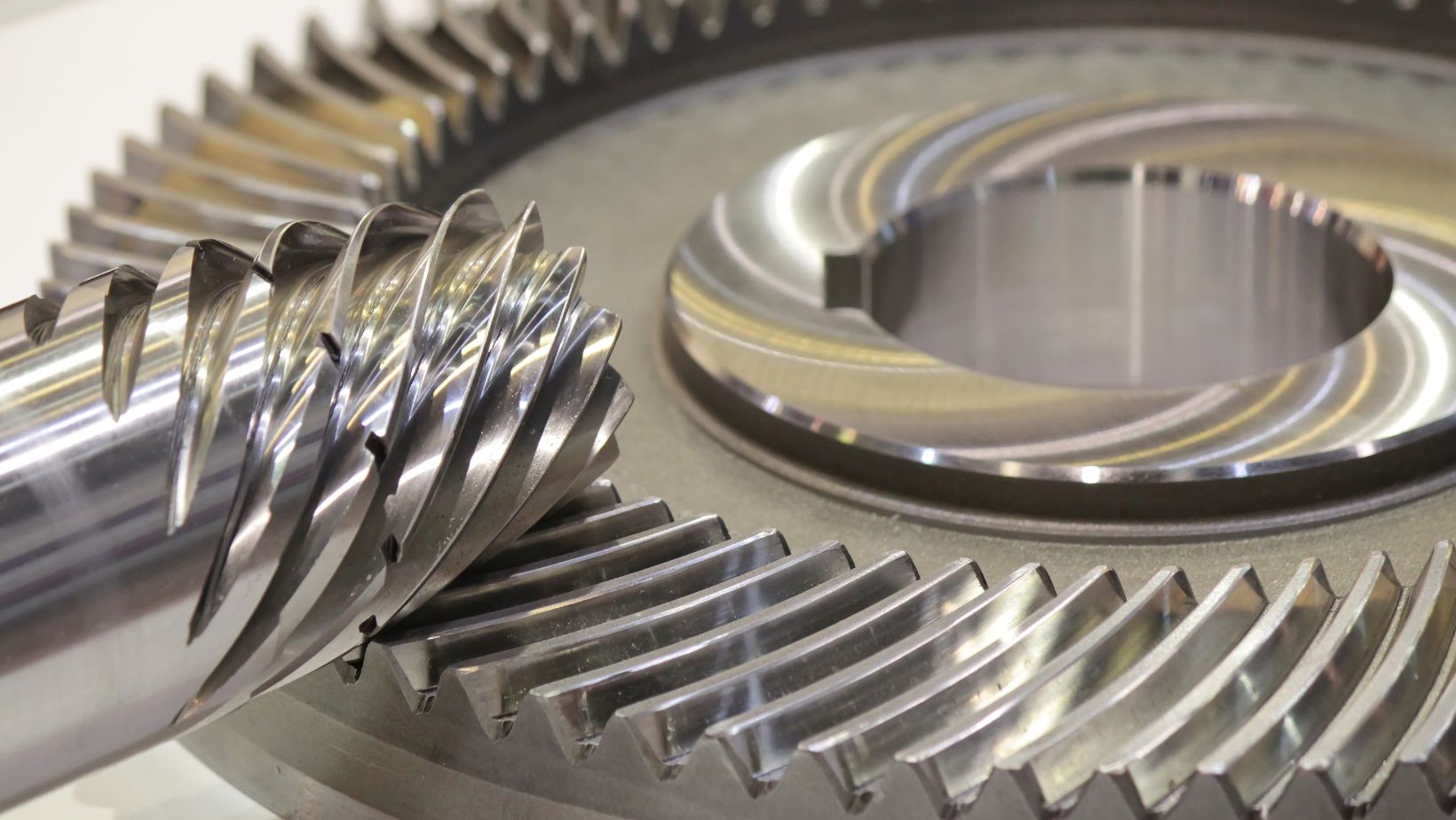

Creating precise beveled edges on metal parts for many manufacturing businesses is crucial for producing high-quality welds and achieving professional finishes. But how can you integrate advanced bevel cutting capabilities into your CNC plasma cutting machine?

Integrating advanced bevel cutting requires installing a specialized beveling head attachment, upgrading control software to handle multi-axis movements, and implementing height control systems to maintain proper torch angles and distances.

While this basic answer provides a starting point, several critical factors will need to be considered based on your specific machine model, production requirements, and budget constraints. Understanding these variables will help you make the right choices for your particular setup and avoid costly mistakes during the upgrade process.

What Factors Should I Consider Before Adding Bevel Cutting Capabilities?

Before investing in bevel cutting upgrades, evaluate your machine’s structural integrity and load-bearing capacity. The additional weight and torque from a beveling head can stress older or lighter-duty machines beyond their limits.

Your power supply must also be capable of handling bevel cuts, which typically require 20-30% more power than straight cuts due to the increased material thickness at angles. A 100-amp system might be sufficient for straight cuts but could struggle with consistent bevel performance.

Control system compatibility is another crucial consideration. Many older CNC controllers lack the processing power or software capabilities to handle the complex geometric calculations required for precise bevel movements. You may need to upgrade your entire control system to achieve reliable results.

Which Type Of Beveling Head Is Right For My Operation?

There are three main types of beveling heads available: mechanical tilt, infinite rotation, and fixed angle. Mechanical tilt heads are most common for job shops, offering flexibility up to 45 degrees but requiring more maintenance. Infinite rotation heads cost more but excel in high-production environments where continuous beveling is needed.

Fixed angle heads are the most economical choice but limit you to preset angles, typically 30, 45, or 60 degrees. They’re ideal for operations that consistently cut the same bevel angle and don’t require frequent adjustments.

How Much Will This Upgrade Impact My Production Schedule?

Installing bevel cutting capabilities typically requires 2-5 days of machine downtime for mechanical installation and initial calibration. However, the learning curve for operators can extend this implementation period significantly.

Expect to spend 2-3 weeks getting operators comfortable with the new technology and achieving consistent results. During this period, production speeds may decrease by 30-40% as your team adapts to the new processes and parameters.

Consider scheduling the upgrade during planned maintenance periods or slower production cycles to minimize impact on customer deliveries. Many manufacturers find it helpful to maintain some straight cutting capability during the transition period.

What Are The Common Challenges When First Using Bevel Cutting?

The most frequent challenge newcomers face is achieving consistent bevel angles across the entire cut length. This usually stems from improper torch height control settings or inadequate understanding of how cutting speed affects bevel quality.

Material warping can also present significant difficulties during bevel cutting. As the material heats unevenly due to the angular cut, it tends to distort more than with straight cuts. Installing proper hold-down clamps and implementing pre-heating strategies can help minimize this issue.

Another common stumbling block is managing consumable wear. Due to the more intense heat exposure at angles, bevel cutting typically increases consumable wear by 40-50% compared to straight cutting. Establishing a regular inspection and replacement schedule becomes even more critical with bevel operations.

How Can I Optimize My Bevel Cutting For Maximum Efficiency?

Invest in proper training for operators and programmers. Understanding how to nest beveled parts properly can improve material utilization by 15-20% compared to basic nesting approaches. Additionally, well-trained operators can spot potential issues before they affect part quality.

Modern plasma cutting technology continues to evolve, with software improvements that can automatically adjust cutting parameters based on material feedback data. These advancements allow for more consistent bevel quality across various material types and thicknesses.

Consider implementing automated tool path generation software designed explicitly for bevel cutting. These systems can reduce programming time by up to 60% while ensuring optimal cutting sequences and reducing the risk of collision between the torch and previously cut parts.

Conclusion

Before making any purchases or modifications to your existing CNC plasma cutting system, schedule a consultation with your machine’s manufacturer or an authorized retrofit specialist. They can perform a detailed assessment of your current setup and provide specific recommendations that align with your production needs and equipment capabilities, ensuring you make the most informed decision for implementing bevel cutting into your operations.